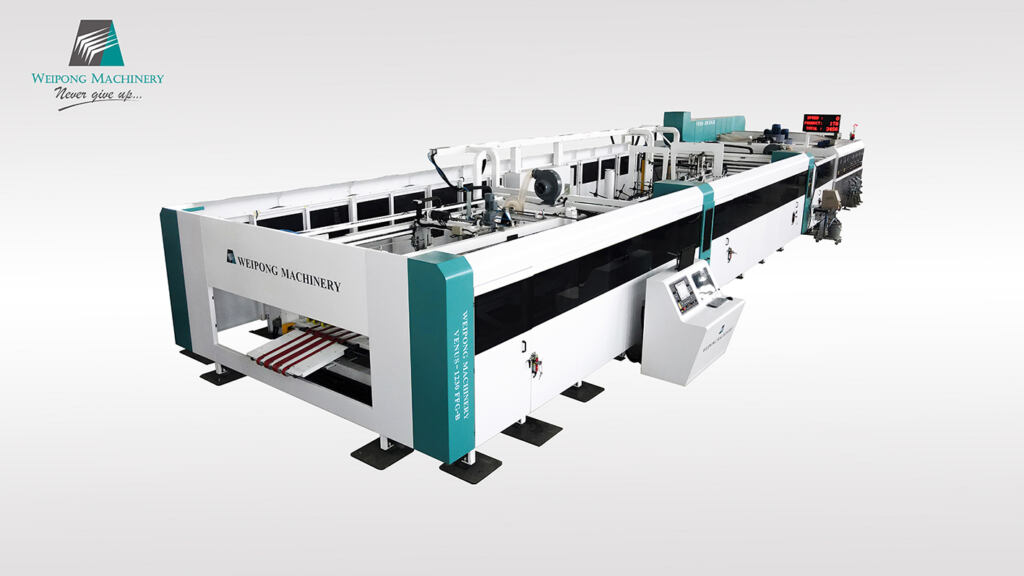

CCMSWIFTLINE Ausführungen

Flexo-Serie: Variantenreich und individuell

- Flexo-Vordruckmaschine mit Überführungsstation in Flachbettstanze

- Flexo-Druck-/ Slotter mit Stanzbaustein und Bogenstapler

- Flexo-Rotationsstanze mit Ausbrechstation und Bogenstapler

- Flexo Folder Gluer mit Zähler/Stapler (Stapelbildung von oben) und wahlweise Heftstation

- Verschiedene Maschinengrößen für Formate von 800 mm x 2000 mm bis 2500 mm x 5000 mm

CCMSWIFTLINE Allgemein

- Etablierter Maschinenhersteller Weipong Machinery

- Stabile Maschinenkonstruktion und hochwertige Verarbeitung

- Verfahrbare einzelne Bausteine mit pneumatischer Verriegelung

- Automatische Ölschmierung mit Niveauausgleich

- Geschliffene, gehärtete Zahnräder, sowie verchromte Wellen

- Automatische Formateinstellung über Zentralcomputer

- Speichern von Wiederholaufträgen

- Motorische Kalibereinstellung

- Unabhängige Einstellungen an allen Bausteinen über Touch Screen Monitor

- SPS Steuerung inklusive Fernwartung

- Elektrische und mechanische Standardkomponenten namhafter Hersteller

CCMSWIFTLINE Automatischer Bogeneinschub

- 4-Reihen Rollen Lead edge Bogeneinschub

- Elektronische Einstellung auf Skip Feed-Funktion

- Motorische Verstellung der Einschublänge

- Große Ansaugfläche mit positionierbaren Schließklappen

- Staubabsaugung

- Automatische 0 – Stellung

- Crushless Bogeneinschub möglich

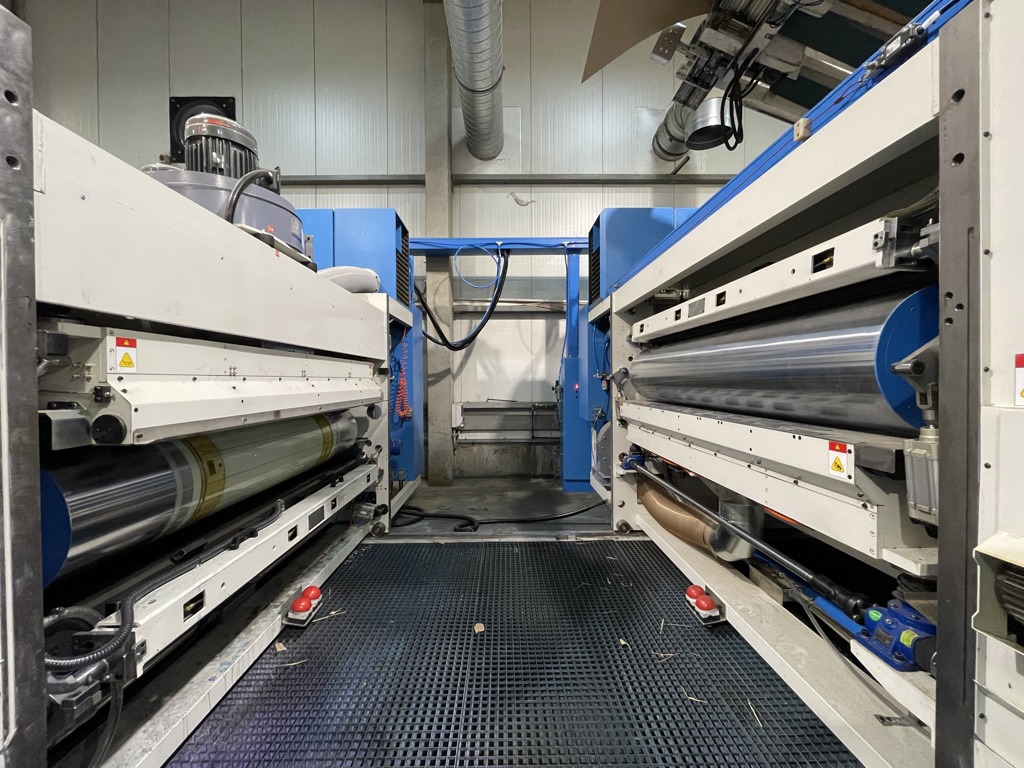

CCMSWIFTLINE Flexo Druckwerk

- Wahlweise mit Druck von unten oder oben

- Als Standard Druckwerk oder mit Vakuumtransport

- Drucksystem mit Gummiwalze oder Kammerrakel

- Keramik-Rasterwalze mit Rasterung nach Kundenwunsch

- Klischeezylinder hart verchromt

- Klischeebefestigung mit Matthew’s Fast Lock oder Spannsystem mit Klemmwelle

- Automatische Druckfunktion und separater Waschmodus

- ARO Membran Farbpumpe

CCMSWIFTLINE Motorischer Schlitzbaustein

- Wahlweise als einfacher – oder doppelter Slotter Baustein

- Zusätzliche Welle mit Vorquetschkörpern

- Ausführung mit normalen-, oder gedrehten Schlitzmesserkörpern

- Motorische Messer- und Messerkörperverstellung

- Gezahnte Segmentmesser mit Hohlschliff

- Schneiden der Abknipsmesser für Leimlasche gegen Stahlring

- Motorische seitliche Verstellung aller Körper über hochwertige Gewindespindeln

- Seitliche Körperverstellung zur genauen Positionierung

CCMSWIFTLINE Stanzbaustein

- Wahlweise mechanisch mit Maschine verbunden, oder mit eigenem Servo-Antrieb

- Seitlich oszillierender Stanzzylinder

- Abschleifvorrichtung zum Glätten der Stanzbeläge

- Geschwindigkeitsangleichung nach erfolgtem abschleifen der Stanzbeläge

CCMSWIFTLINE Vakuum Faltstation

- Faltung nach oben oder unten

- Eigenständig angetriebene Vakuum-Faltstation

- Stabile Konstruktion gewährleistet ruhigen Lauf auch bei hohen Geschwindigkeiten

- Elektronisches Leimwerk wahlweise rechts oder links montiert

- Vakuumtransportbänder mit Hochleistungssaugmotoren

- Multi T-Faltgurte zur Vermeidung des Fischschwanzeffektes

- Seitliche Führungsrollen mit unterschiedlichen Öffnungen ab 90° Faltvorgang

- Hauptfunktionen motorisch verstellbar inklusive Faltschwerter und seitliche Führungsrollen

- Heftstation mit oszillierendem Heftkopf und vorgeschalteter Ausrichtstation lieferbar (bei Faltung nach oben)

CCMSWIFTLINE Zähler/Stapler

- High Speed Zähler/Stapler

- Einlauf der Formate von oben mit Stapeltrennung und sicherem Abtransport

- Vollautomatische Verstellung bei Formatwechsel

- Gesamter Arbeitsablauf während der Produktion über Servo-Technik

- Stückzahlvorwahl der einzelnen Schachteln im Stapel mit Stapelzählung